Execute, Track and Report

After configuring the real time browser based Manufacturing Execution System EZ-MES, this system can be used to execute manufacturing processes. During execution, instructions can be shown to workers such as visual assembly diagrams or overviews of procedures. In each execution step, data can be gathered either via user inputs or automated inputs. EZ-MES offers different ways to track parts. Data collection can be based on individual parts or batch processing. Where products can get a unique identifier, like a serial ID. And of course lot tracking is supported as well. To generate reports, EZ-MES contains a number of pre-defined templates and can be expanded by defining your own reporting templates.

Execution of a manufacturing process

A Work Order or Job Order is received by an organization from a customer, or created within the organization. Such an order may be for products, services or both. It is used to signal the start of a manufacturing process and typically is linked to produce parts with a Bill of Material (BOM). Hence, the order will probably state:

- The quantity of the product to be manufactured, built or fabricated

- The raw material to be used, its price and amount

- The production flow to be used to fulfill the order

In EZ-MES, a Work Order will initiate one or more Travelers. After initiation, travelers will then move parts around during production by execution. Travelers can be tracked, traced, reported, documented and finalized.

EZ-MES support the configuration and use of Triggers on Travelers. Such a trigger can, for example, initiate e-mail Notifications when certain events in production occur. Typicallly, let EZ-MES send notifications to supervisors in case some exception like a hold was detected during a production step.

Track and Traceability

Travellers in EZ-MES are used for tracking the production. For a large number of industries and applications, full forward (to customer) and backward (to supplier) traceability is required. EZ-MES will offer you full traceability for all your production processes, including:

- The origin of materials and parts

- The processing history

- The distribution and location of the product after delivery

Whenever something goes wrong with one of your products, you would like to be able:

- Create a new Traveler to support the RMA

- See how the product was created

- Know exactly which procedures were use

- Backtrack the materials that went into it

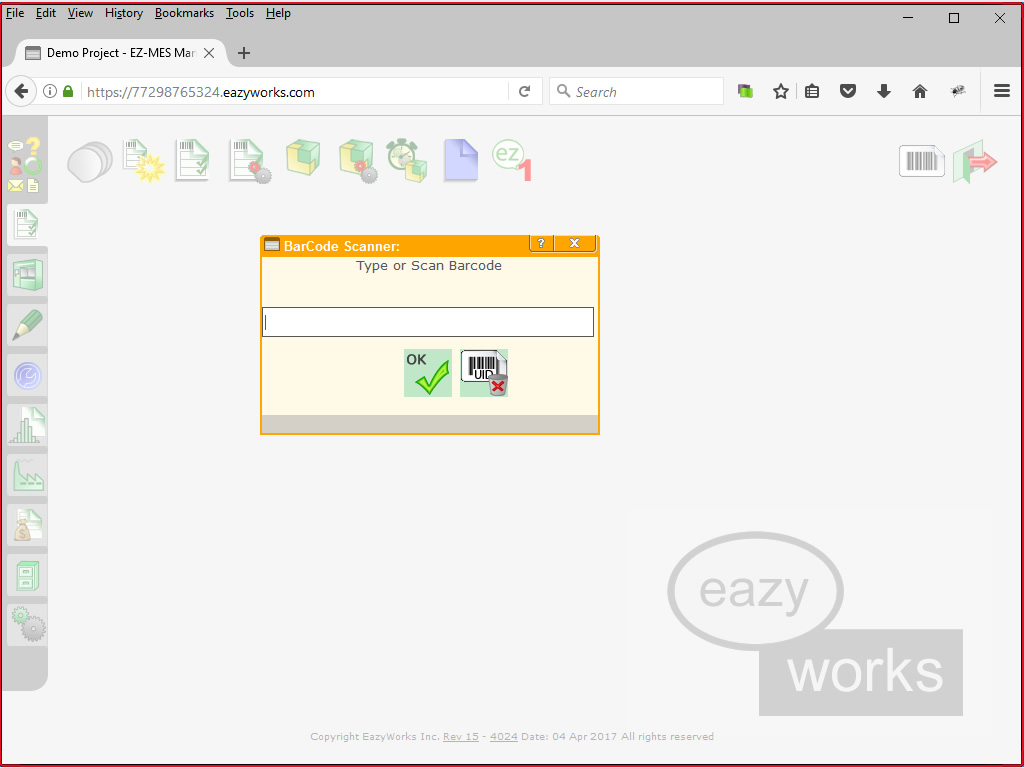

You can simply type or scan the batch or serial number of the product into EZ-MES, and with a single click, you get a full history report for this specific product.

This is knows as backward traceability. Based on the information you get from the history of the product that has a problem, you can find the root cause of an occurred problem. This could be one of the following:

- A piece of equipment that was not calibrated

- Material supplied by one of your vendors that had a problem

- A glue that expired

- An employee that was not correctly trained

- A work instruction that was not properly updated

For each of these possible cases you would like to know which other products could be affected. This is known as forward traceability.

Generate reports

Accurate and timely production reports are key to the management and operator decision making process in manufacturing. EZ-MES contains pre-defined Templates for the following report types:

- Purchase Order Report

- Work Order Report

- Traveler Report

- Part Record Report

- Inventory Report

- WIP Report

- Throughput Report

For the purpose of data analyses, SPC report can be created.

Screenshots

Simply scan a part in EZ-MES to get detailed information such as how and when it was created, who worked on it, which work instructions were used and more...

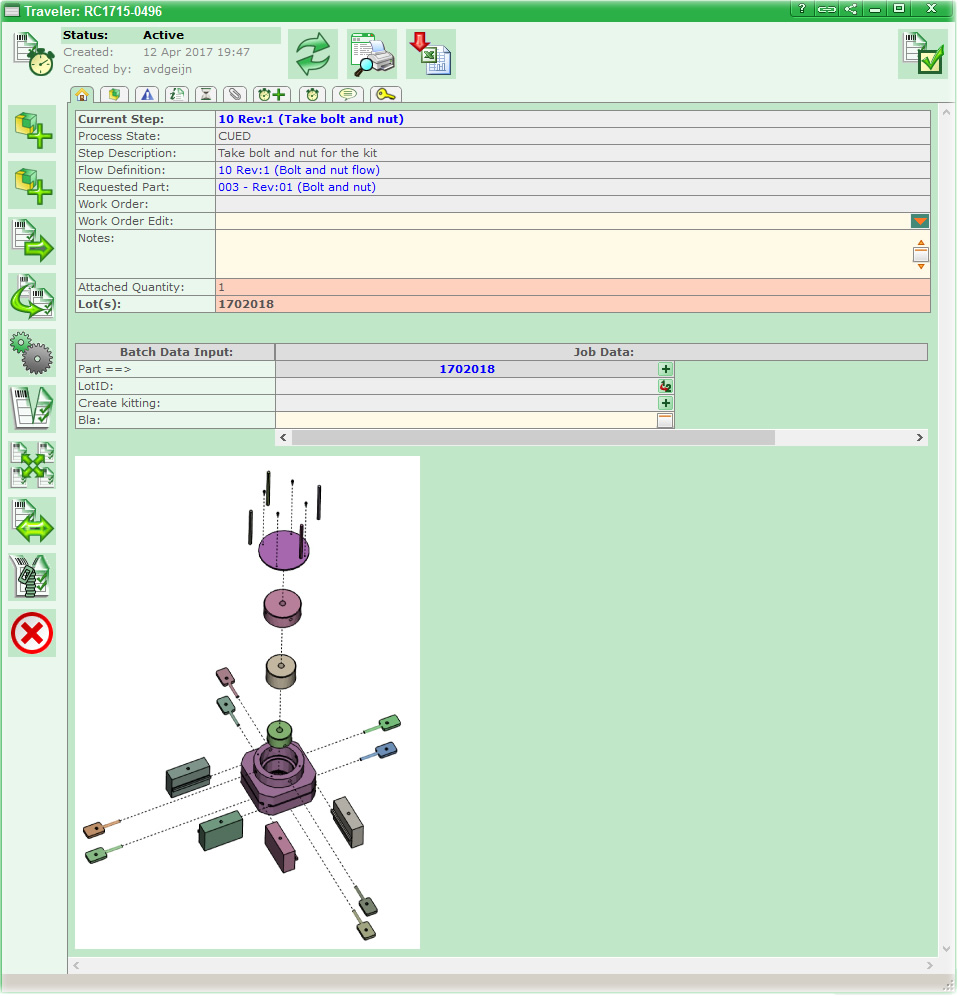

While executing a process step, EZ-MES shows work instruction with a drawing of the assembled part

Example of a configurable Traveler Report in EZ-MEZ